(806) 451-3101

(806) 451-3101

Walk-In Cooler Installation Contractor in Lubbock

If you are needing to replace or purchase a new walk-in cooler, we offer a comprehensive installation service, from helping you select a cost-effective and energy-efficient model to install it with a focus on quality. West-Tex Air & Refrigeration of Lubbock has many years of experience in all types of walk-in cooler installations. We are happy to help you get your new walk-in cooler installed and running. Choose from several manufacturers.

Commercial Refrigeration Installation

Purchasing commercial refrigeration equipment can be challenging and sometimes a huge undertaking. Making sure the refrigeration product will serve your refrigeration needs and last a long time will have a huge impact on your bottom line. Danny Klos, the proud owner of West-Tex Air & Refrigeration of Lubbock will answer all your questions and educate you on the entire refrigeration installation process.

West-Tex Air & Refrigeration of Lubbock has installed, repaired, designed, and maintained hundreds of all types of refrigeration systems over the years. Call us and we’ll schedule a time for West-Tex Air & Refrigeration of Lubbock to meet you at your place of business to assess your commercial refrigeration needs.

West-Tex Air & Refrigeration of Lubbock knows just what it takes to get you the right commercial refrigeration equipment at the right price. We have all of the latest models, and whether this is a first time purchase for you or you just need to replace your old refrigeration equipment, we can make the whole process much easier for you. Just ask any of our Lubbock area commercial refrigeration customers and you’re sure to find that our reputation is stellar anywhere in Texas.

Refrigeration Installation

Whether it’s a walk in freezer, walk-in cooler, reach in cooler, or any ice machine brand, all commercial refrigeration equipment needs to be installed properly and professionally so that you can be sure it will work the way it is designed to. You need to be able to count on your equipment and that is why TriPoint Refrigeration, Inc. is the right choice for all of your commercial refrigeration installation needs.

Many Years of Walk in Cooler Installation Experts

Our technicians have many years of experience working with all types of commercial refrigeration equipment and they will be able to get your refrigeration units up and running in no time. Our customers can rest assured that the work is being done right the first time, every time.

Our Services:

- Refrigeration Repair

- Refrigeration Sales

- Refrigeration Installation

- Refrigeration Maintenance

- Ice Machine Repair

- Ice Machine Sales

- Ice Machine Installation

- Ice Machine Leasing

- Ice Machine Maintenance

- Walk in Freezer Repair

- Walk in Freezer Sales

- Walk in Freezer Design

- Walk in Freezer Installation

- Walk in Freezer Maintenance

- Commercial HVAC Repair

- Commercial HVAC Sales

- Commercial HVAC Design

- Commercial HVAC Maintenance

- Commercial HVAC New Construction

- Energy Management

Publication No. RU-RHX-1120A

Replaces RU-RHX-0820B

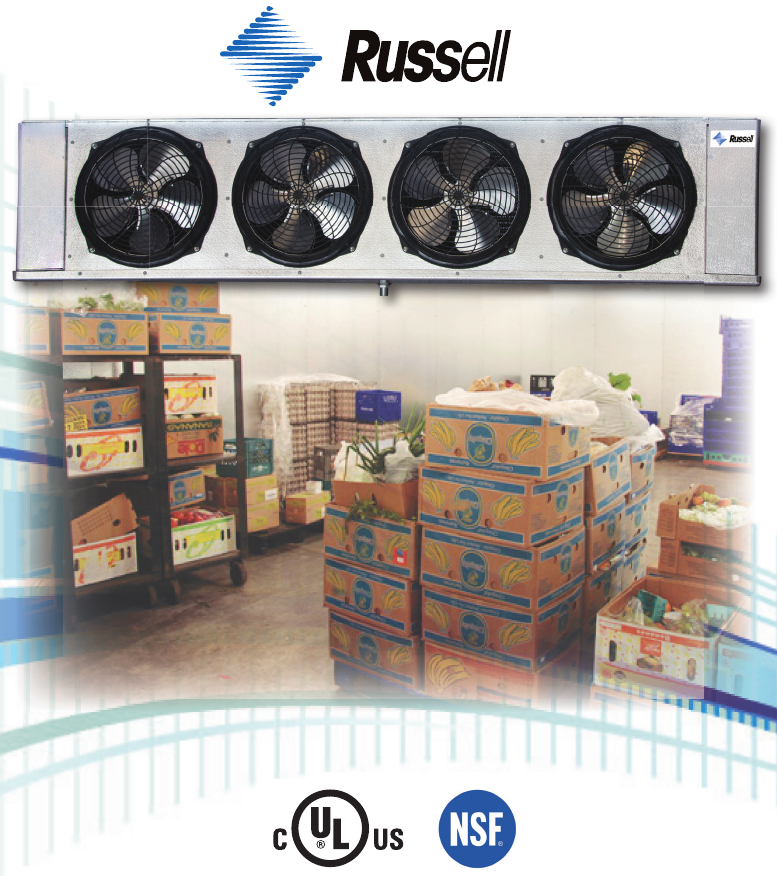

HEAVY DUTY UNIT COOLER

Medium to Large Walk-Ins - Cooler and Freezer Applications

Designed for Walk-in Coolers and Freezers in boxes less than 3,000 sq. ft.

Air Defrost

31,200 to 253,100 BTUH

Electric Defrost

33,100 to 227,400 BTUH

Hot Gas Defrost

33,100 to 227,400 BTUH

Models were designed in anticipation of the July 2020 Department of Energy Annual Walk-in Energy Factor (AWEF) regulations for evaporators for Walk-in Coolers and Freezers in boxes less than 3,000 sq. ft. See pages 13-14 for AWEF compliance ratings.

HEAVY DUTY WALK-IN COOLER UNIT

Cooler Features

Walk-In Cooler Sizes

There are a wide array of sizes to match your specific application requirements ranging from 31,200 to 253,100 BTUH at a 10° TD. Models are available with air flow spanning a range of 5,750 to 24,000 CFM.

Walk-In Cooler Housing

Each unit is constructed with a rust-free, heavy gauge, textured, aluminum housing which is lightweight yet extremely durable. Models feature hinged drain pans to allow for convenient servicing and maintenance. Pre-drilled hanger holes are provided on all units for fast installation.

Cooler Coil

Seamless copper tubes are staggered and mechanically expanded into heavy-gauge corrugated aluminum fins to assure maximum heat transfer. Die-formed fin collars are provided for accurate fin spacing. Heavy gauge hangers are fastened directly to the tube sheet of the coil to provide high structural strength. Electric Defrost and Hot Gas Defrost Models are available in both 6 FPI and 4 FPI.

Cooler Motors

Standard models feature highly efficient Dual Speed Electronically Commutated (EC) motors. which are compliant with California Title 24 regulations1.

Cooler Fans & Cooler Guards

Powerful heavy-duty aluminum fans are individually balanced to provide vibration-free operation. Standard heavy-gauge wire fan guards are UL/cUL-approved epoxy coated for corrosion resistance. Air throw for Heavy Duty Unit Coolers is 100 ft.

Cooler Refrigerants

Heavy Duty Unit Coolers are optimized for multiple refrigerants including R404A, R407A, R448A, R449A, and R744 DX (CO2). Please specify system refrigerant requirements when ordering. A separate compartment is provided for all refrigerant connections which allows ample room for internal mounting of expansion valves.

Electrical

Available in 208/230V/12, 208-230V/3, 460V/1, or 460/3. A large compartment is supplied for all electrical components and is easily accessible by removing the end panel. All models are UL and cUL listed.AIR DEFROSTAir Defrost models (RH6A) are designed for use in coolers at +35°F and warmer.

Electric Walk-In Cooler Defrost

Electric Defrost models (RH6E or RH4E) are designed for use in coolers and freezers between 35°F to -30°F. Electric Defrost 4 FPI models (RH4E) are designed for use in freezers between 32°F and -30°F. Defrost heaters are mounted on the air intake side of the unit for optimal performance and easy maintenance. A lower heater is installed inside the drain pan for fast, reliable drainage. Fixed defrost termination, fan delay and heater safety controls are factory mounted for optimum performance of each control function.

Hot Gas Defrost

There are two types of Hot Gas Defrost models available: 3-pipe Hot Gas models (RH*H or RH*K) and 2-pipe Hot Gas Reverse Cycle units (RH*G or RH*L). Hot Gas Defrost 6 FPI models (RH6H, RH6K, RH6G, RH6L) are designed for use in coolers and freezers between 35°F and -30°F. Hot Gas Defrost 4 FPI models (RH4H, RH4K, RH4G, RH4L) are designed for use in freezers between 32°F and -30°F. All units include fixed defrost termination and fan delay controls which are factory mounted for optimum performance of each control function. Refer to the current Russell Technical Bulletin for piping. Reverse Cycle units can also be used for Alternating Evaporator Systems.

Optional Features

- EcoNet® Enabled Controller3 (factory-installed)

- EcoNet® Command Center (loose)

- Reverse Connections

- Thermostat - Mechanical or Electric (mounted or loose)

- Thermostatic Expansion Valve (mounted or loose)

- Electronic Expansion Valve (mounted or loose)

- Liquid Line Solenoid Valve (mounted or loose)

- Insulated Drain Pan • Painted Cabinet (White or Black)

- Coated Cabinet • Stainless Steel Cabinet

- Coated Coil (Bronz-Glow, or Electrofin®)

- Heat Exchanger (loose)

Notes

* AWEF (Annual Walk-in Energy Factor)

1. Single Compressor system without variable capacity.

2. Some limitations apply. For specific electrical offering, consult electrical data tables in this brochure.

3. EcoNet Control Package includes EEV; suction pressure transducer; suction, entering air coil temp. thermistors; thru-the-door disconnect switch; local on-board two-row backlit LCD display and push-button adjustments. (Controller replaces TXV, liquid line solenoid valve, room thermostat, defrost termination and fan delay, and time clock.)

Publication No. RU-RLX-0720A

Replaces RU-RLX-0719A and all previous versions

Next-Gen All-Temp

LOW PROFILE UNIT Walk-In COOLER

Small to Medium Walk-Ins

Cooler and Freezer Applications

Air Defrost

4,100 to 45,900 BTUH

Electric Defrost

2,700 to 33,000 BTUH

Hot Gas Defrost

2,700 to 33,000 BTUH

NEXT-GEN ALL-TEMP

Walk-In Cooler Features

Russell All-Temps was the original low profile unit coolers with the air draw-through design that established the industry standard as being the all-purpose model for walk-in coolers, freezers, and other applications. We’ve taken these unit coolers to the next level with the release of the Next-Gen All-Temp models. The units feature a new fan guard design and deep draw venturi to achieve optimal airflow and easy access for serviceability. These models can be used with multiple refrigerants, and are available in air, electric, and hot gas defrost configurations.

Walk-In Cooler Sizes

There are a wide array of sizes available with capacities ranging from 2,700 to 45,900 BTUH at a 10° TD. One through six fan models is available with airflow spanning a range of 800 to 4,650 CFM.

Walk-In Cooler Housing

Electric Defrost 6 FPI models (RL6E) are designed for use in coolers and freezers between 34°F to -20°F. Electric Defrost 4 FPI models (RL4E) are designed for use in freezers between 32°F to -20°F. Defrost heaters are mounted on the air intake side of the unit for optimal performance and easy maintenance. A lower heater is installed inside the drain pan for fast, reliable drainage. A defrost termination fan delay thermostat (DTFD) terminates the defrost cycle when the temperature is satisfied. The fan delay allows the warm coil to cool after a defrost cycle prior to the fans turning on. A heater safety thermostat is installed to prevent overheating.

The embossed aluminum casing is lightweight yet durable. Each fan section is baffled to prevent short cycling of the discharge air. The units are designed to mount flush to the ceiling and are compliant with NSF requirements. The top panel includes 1/2” wide slotted mounting points to simplify installation. The removable drain fitting is installed into the bottom of the drain pan for easy field connection and it can be quickly replaced without changing out the entire drain pan. End panels can be slid out from the front of the unit providing easy serviceability from the front or side of the unit, allowing convenient access to the roomy electrical and piping compartments.

Cooler Coil

Copper hairpins consist of high-efficiency 3/8” enhanced copper tubes which are staggered and mechanically expanded into corrugated aluminum fins achieving maximum heat transfer while reducing the refrigerant charge. Die-formed fin collars provide even fin spacing. Models are available in 4 and 6 fins per inch (FPI). Sweat connections are standard on all models.

Cooler Motors

Standard models feature highly efficient Dual Speed Electronically Commutated (EC) motors. Dual Speed EC motors are available for 115V or 208/230V and are compliant with California Title 24 regulations. All motors include thermal overload protection.

Cooler Fans

Heavy-duty 12” aluminum fans are balanced to provide vibration-free operation. Improved black plastic fan guard design and deep draw venturi achieve optimal air pattern.

Cooler Refrigerants

Heavy Duty Unit Coolers are optimized for multiple refrigerants including R404A, R407A, R448A, R449A, and R744 DX (CO2). Please specify system refrigerant requirements when ordering. A separate compartment is provided for all refrigerant connections which allows ample room for internal mounting of expansion valves.

Electrical

Available for 115V and 208/230V. A large electrical compartment is supplied internally to the unit to house the electrical components and is easily accessible by removing the slide-out end panel. All models are UL and cUL listed and are available for 60 Hz or 50 Hz applications.

Cooler Air Defrost

Air Defrost models (RL6A) are designed for use in coolers 35°F and warmer. All components are factory wired to convenient screw-type terminal strips.

Electric Walk-In Cooler Defrost

Electric Defrost 6 FPI models (RL6E) are designed for use in coolers and freezers between 34°F to -20°F. Electric Defrost 4 FPI models (RL4E) are designed for use in freezers between 32°F to -20°F. Defrost heaters are mounted on the air intake side of the unit for optimal performance and easy maintenance. A lower heater is installed inside the drain pan for fast, reliable drainage. A defrost termination fan delay thermostat (DTFD) terminates the defrost cycle when the temperature is satisfied. The fan delay allows the warm coil to cool after a defrost cycle prior to the fans turning on. A heater safety thermostat is installed to prevent overheating.

Hot Gas Defrost

There are two types of Hot Gas Defrost models available: 3-pipe Hot Gas models (RL*H) and 2-pipe Hot Gas Reverse Cycle units (RL*G) (see pages 8 and 9 for more details). Hot Gas Defrost 6 FPI models (RL6H, RL6G) are designed for use in coolers and freezers between 34°F and -20°F. Hot Gas Defrost 4 FPI models (RL4H, RL4G) are designed for use in freezers between 32°F and -20°F. All Hot Gas units include a fixed DTFD factory wired and an electric drain pan heater.

Optional Features

- EcoNet® Enabled Controller1 factory-installed

- EcoNet® Command Center (loose)

- Thermostat - Mechanical or Electric (mounted or

loose) - Thermostatic Expansion Valve (mounted or loose)

- Electronic Expansion Valve (mounted or loose)

- Liquid Line Solenoid Valve (mounted or loose)

- Insulated Drain Pan

- Painted Cabinet (White or Black)

- Coated Cabinet

- Stainless Steel Cabinet

- Coated Coil (Russproof, Heresite, Bronz-Glow, or Electrofin®)

- Heat Exchanger (loose)

Notes

EcoNet Control Package includes: EEV; suction pressure transducer; suction, entering air coil temp. thermistors; local on-board two-row LCD display and push-button adjustments. (Controller replaces TXV, liquid line solenoid valve, room thermostat, defrost termination and fan delay, and time clock.) EcoNet is not available in 208-230/3/60.

Business Hours: Monday - Friday 8AM - 5PM *24 Hour Emergency Service*

COPYRIGHT© 2016. ALL RIGHTS RESERVED - West-Tex Air & Refrigeration. Walk In Cooler Installation Lubbock

RHAC